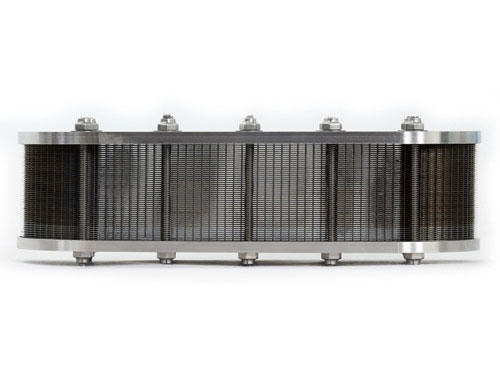

Edare has developed novel manufacturing technologies to build and deliver lightweight, high-efficiency heat exchangers for gas turbine engines, cryocoolers, and other applications. A main benefit of Edare’s laser welding expertise is the hermetic joining of thin metal plates and microtubes using materials such as stainless steel, Inconel 625, titanium, aluminum, and silver. The laser welding process results in an extremely small heat affected zone resulting in high strength, low distortion, precision welded products.

Leveraging these proprietary laser-welding techniques, Edare has manufactured heat exchangers for both rotorcraft and fixed-wing unmanned aerial vehicles, significantly increasing engine efficiency. Edare is also developing techniques to produce larger heat exchangers to support stationary power applications.